Are your Work Orders working for you?

As a green industry business grows, there comes a point where the owner/key manager can no longer be on every single job. Whether you do one-time work or recurring, the reality is at some point you start relying completely on your field staff to execute projects based purely on your verbal or written instructions.

This can be a really difficult transition for most hands-on, boots on the ground oriented business owners. How many times have you thought to yourself, “If I could only clone myself, I would be set!”?

Well that is just it.. Because you can not clone yourself (at least not yet), you have to make the transition from “expert do-er” to “expert explainer”. You need a comprehensive way to download what is in your brain into an easy-to-understand plan that any of your crew leaders/technicians can pick up and run with.

How do you do this? Quality work orders.

Also called job jackets, job plans etc. these are documents that outline the scope of work, items, materials and any other details of a project or service for the field crew to do.

Here are 7 components that should be considered in every Work Order:

1.Creates automatically

Just like any other activity in your business, if it adds work and friction to your day, you likely will not stick with it long term.

The last thing you want to do is to have to rewrite a second document after your client’s proposal re-explaining yourself and the details of the project to your team. To see why double-entry kills your business see my other article here.

When you are doing your on-site estimates all the measurements, materials, photos, drawings etc. can be taken in real time and would all make their way over to the work order without the need for double entry.

Here is an example of what this looks like in SingleOps:

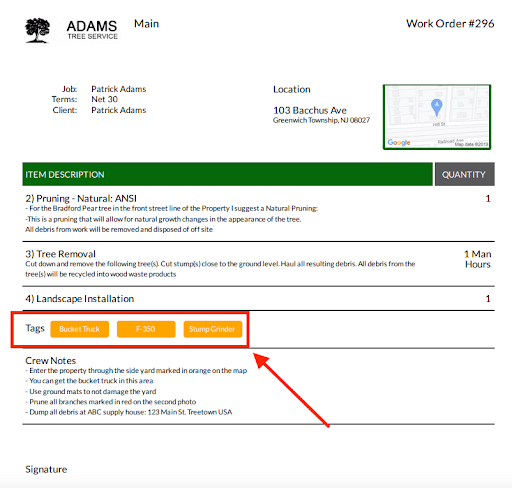

2. It is actually a Work Order

Very often, I find tree & landscape companies just take their accepted carbon copy or PDF proposals and make a copy to hand to the crew to do the work. The challenge with this: there is likely language and details of the job that you would like to communicate differently to your client than your crew. This can cause confusion to your crew and often lacks all the necessary details they need to complete the entirety of the scope of work.

Here is an example: Let’s say the job is to prune a large tree in the backyard..

On the Proposal to the client:

- For the Bradford Pear tree in the front street line of the Property I suggest a Natural Pruning: This is a pruning that will allow for natural growth changes in the appearance of the tree.

- All debris from work will be removed and disposed of off site

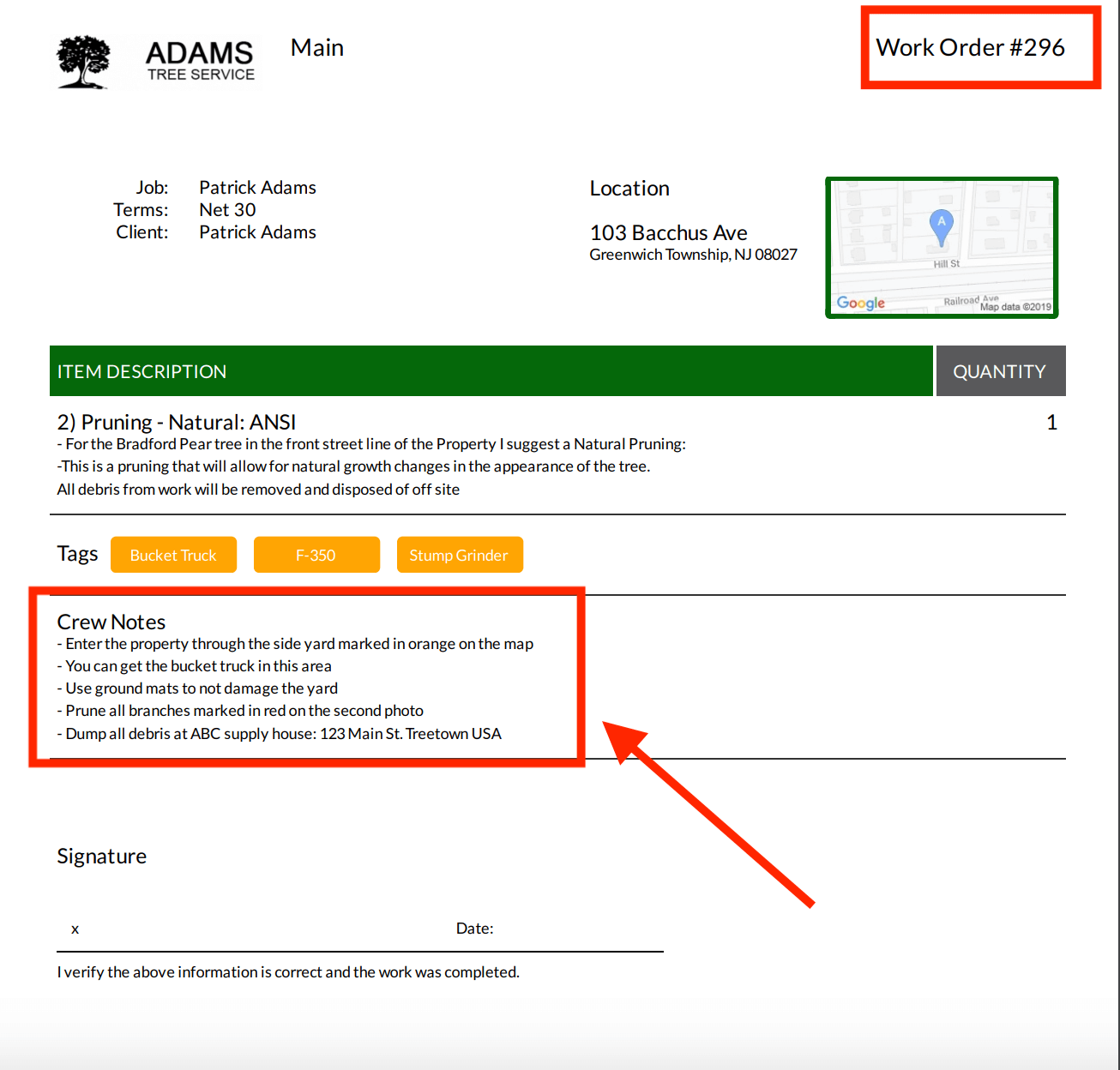

While the crew needs additional information: (see crew notes)

– Enter the property through the side yard marked in orange on the map

– You can get the bucket truck in this area

– Use ground mats to not damage the yard

– Prune all branches marked in red on the second photo

– Dump all debris at ABC supply house: 123 Main St. Treetown USA

You want there to be two distinct documents that segment out the information based on the audience that is viewing the document.

Lastly, the word “Work Order” with a specified “#” should be present on the document. This can make for easy tracking and referencing in the future and can also be a vital component for commercial/industrial work where client’s may require a “reference number”.

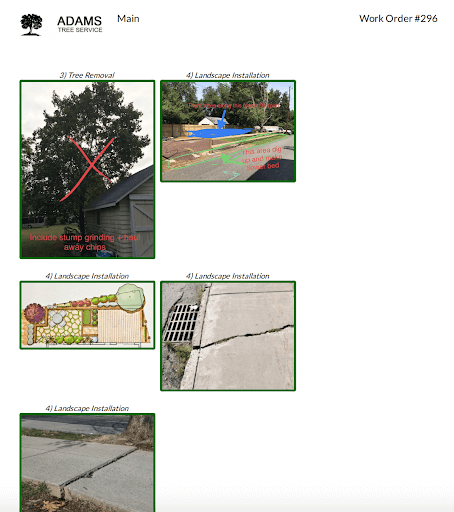

3. Contains Photos

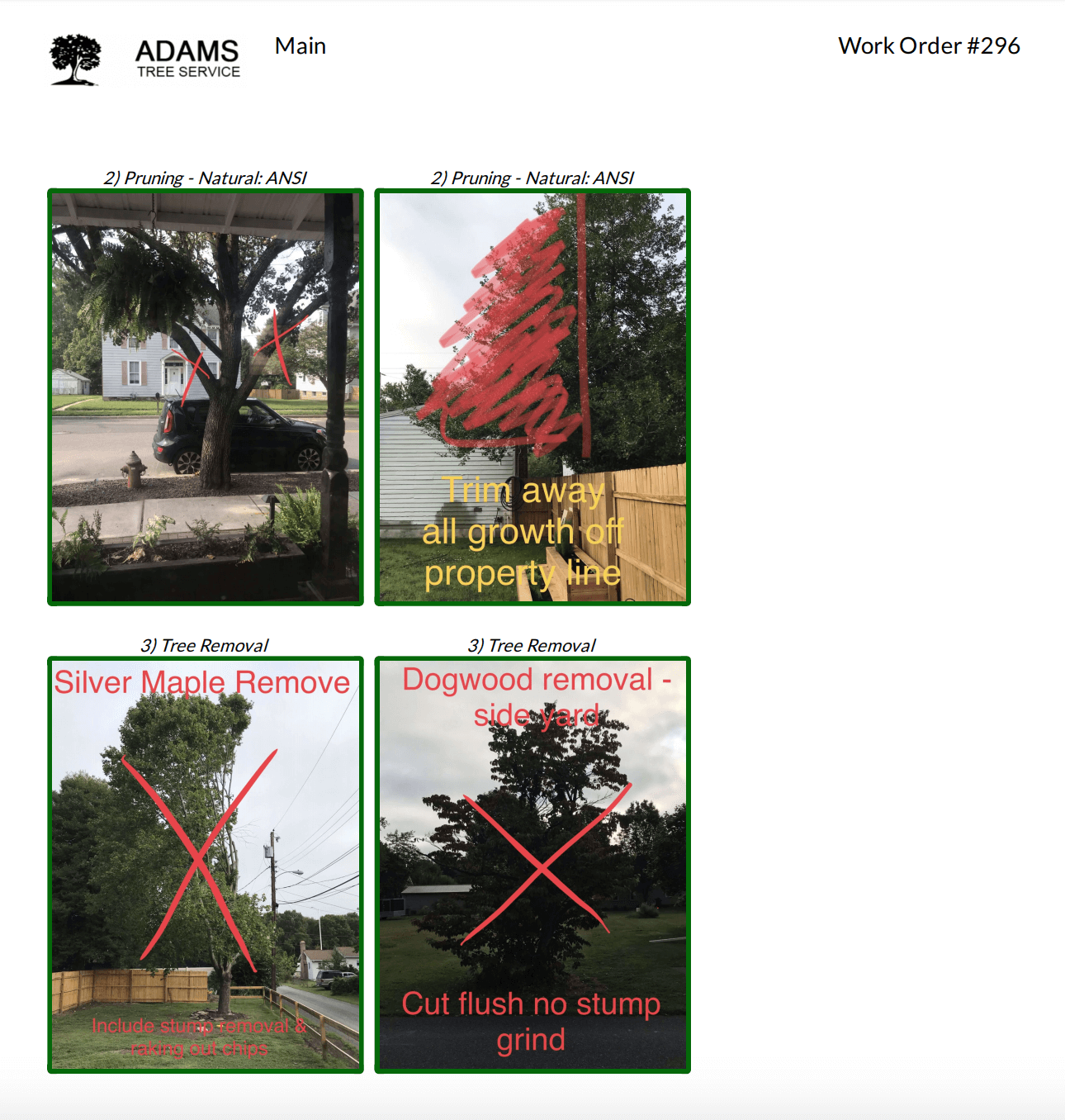

Because you or your estimator can not physically be on site to set up the jobs for the crews, it is critical that there is abundant visual explanations of the scope of work through photos.

Photos can be of:

- Specific plants or trees that are included in the scope of work

- Access areas, or restrictions

- General condition challenges: low lying water areas, soft soil, damages

- For liability purposes: existing damage, broken concrete, ruts in the soil

- Mark up on photos for removals or additions

Here are some good examples that would be taken during the on-site estimate and would ideally carry through automatically to the work order:

Using your smartphone or a tablet, you can easily edit and mark up any photo to add in lines, “X’s” drawings etc.

4. List Equipment Needed

If you are anything like I was, early morning shop time is complete chaos. The foreman and technicians frantically asking you/their manager which trucks, equipment and rigs to bring, making sure they have the right trailer and all the right hand tools. Inevitably, the crew forgets something causing a trip back to the shop, completely killing productivity.

A great best practice to adopt is to outline the equipment needed for each job right when you are on site providing the estimate walk through. This is when the information is fresh for you and you can stage out the job while you are on site picking up on all the site conditions.

You can view equipment lists in a couple of different ways:

- Job Costing: this is when you would add equipment to each project and break it down in terms of recovery per hour or per day unit.

- Tag/Note: this is when you are just simply flagging the job with a tag or a note for each piece of equipment needed for that job.

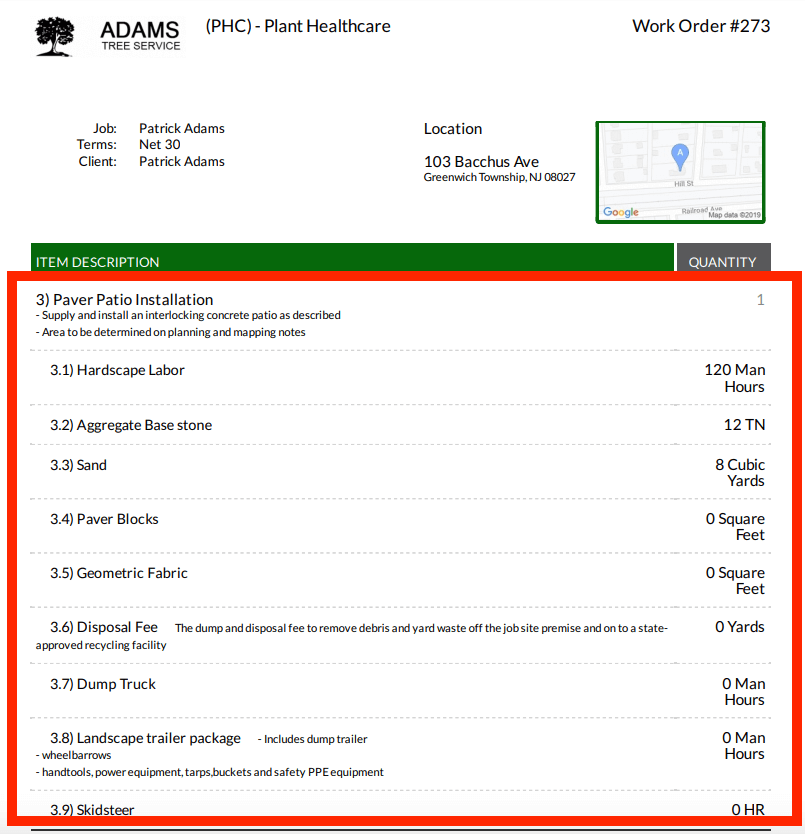

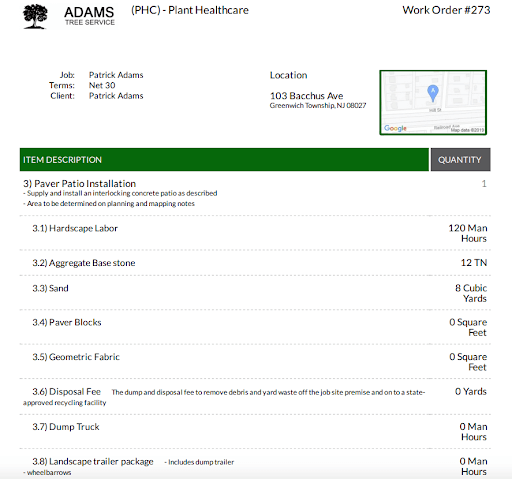

5. Production Expectations

If you are truly going to job cost a project/service, you need to track the “estimated” quantities as well as the “actual quantities”. Looking at the numbers and time spent at the end of the job does not do much of anything if you don’t know your hourly costs, expenses and margins that were originally estimated.

Knowing that you can not always be there on every project means in addition to a clearly described scope of work with photos and mapping, you should be letting your crew know the estimated time they should be taking to complete this work.

A good estimating system will help the salesperson easily capture man hours, equipment utilization and expenses. If that estimating system is integrated, these quantities should show up automatically on the work order for the crew to pickup.

Here are a few items that can help outline expectations on a work order:

- Man-hours: Labor is likely your largest cost. Monitor it and make sure your crews know how much time you estimated it should take for the work to be completed

- Equipment: However you break this down – per hour or just in a list fashion, tell your crew in a list or per unit breakdown what equipment they need to execute this job

- Materials: If the job requires bulk material, plants, chemicals or other products, list out the name, the supplier and the exact quantity expected to use

- Expenses: If the job will incur expenses, disposal fees, toll etc. make sure to spell that out on the work order so the crew can have the proper means to pay for and record all expenses

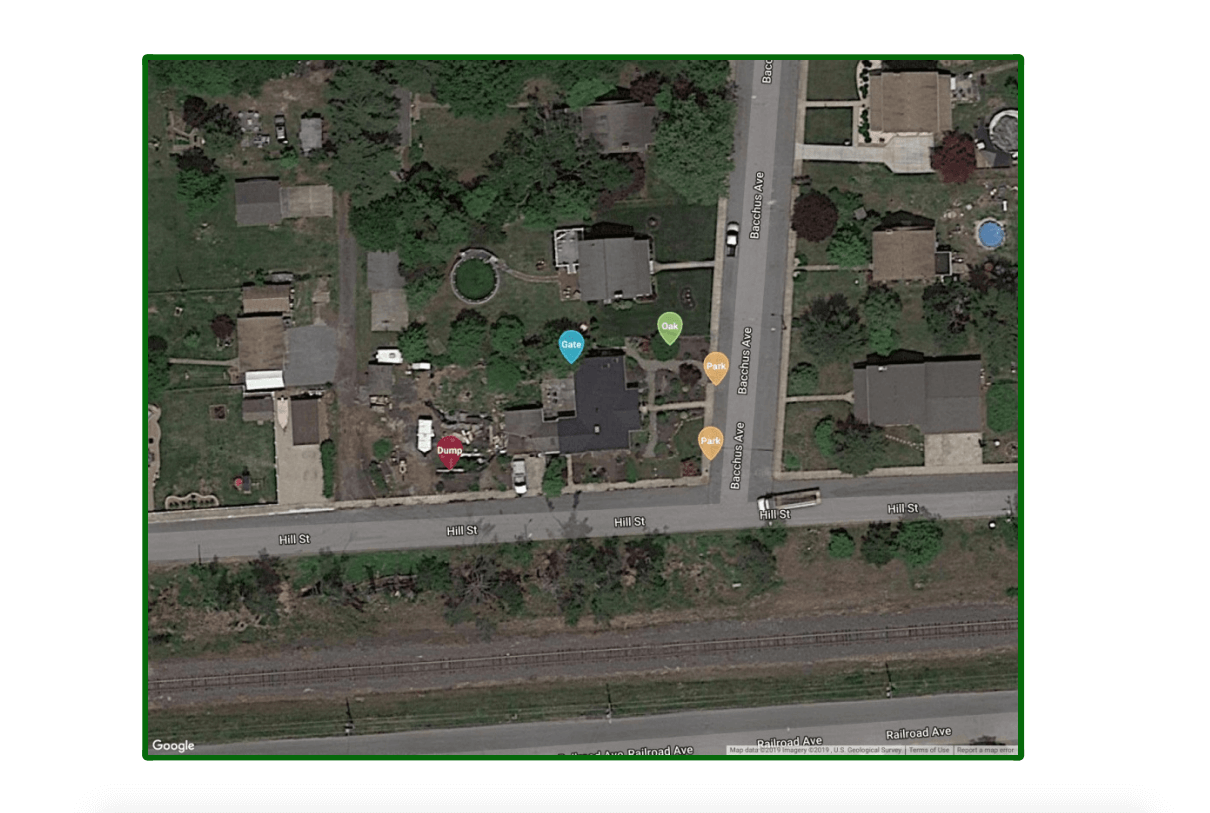

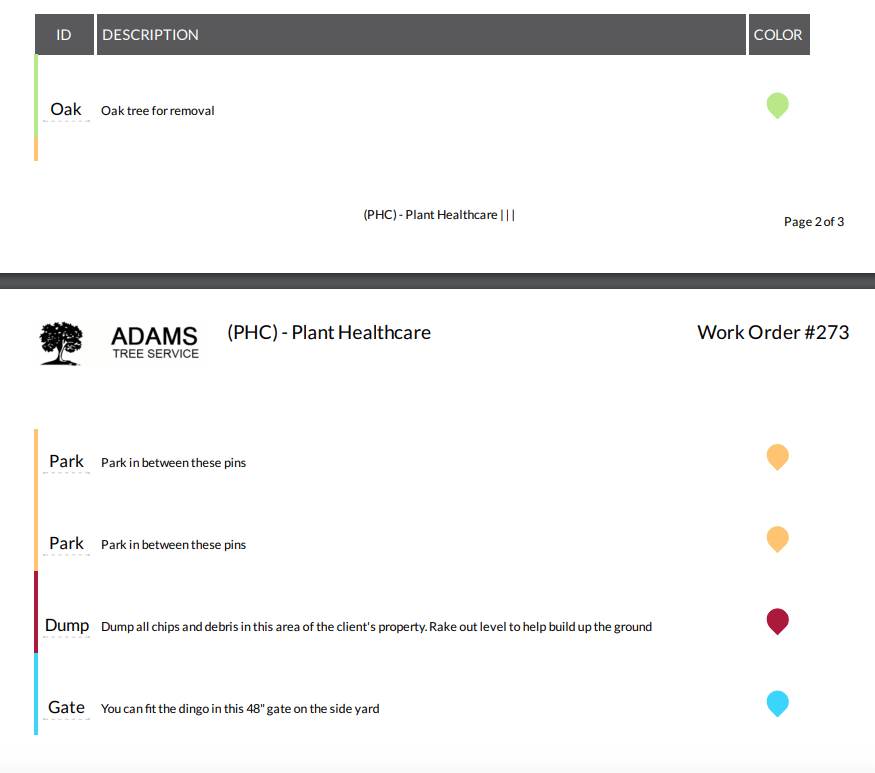

6. Digital Satellite Map

On some jobs, having an overhead view of the property can be helpful to further describe the scope of work and other important details. You may want to drop pins to mark out certain specifics such as:

- Specific trees or plants

- General conditions – low lying areas, wet or water-filled sections

- Entry points

- Parking or staging specifics

- Location of removal or installations

- Location of material setup or debris dump site

This visual representation can be beneficial on estates or commercial projects where you want to layout out descriptions on a larger scale area. A good work order system will have this satellite snapshot pulled in right from the proposal created by the salesperson/estimator. The map will be another layer of detail for the crews making sure they have a holistic view of what needs to happen on this job.

It’s important that the map has a description key on it where you are can elaborate on what the pins are there for:

7. No pricing

In most landscape/tree care companies that I work with, owners do not want their crews to see the total project or service pricing. In most cases, leaving the pricing on a work order can cause confusion and a false sense of reality to field staff members who do not understand the overhead that goes into running a business.

While this may or may not fall in line with your business practices, it is important that your work order system reflects the information that you wish to disclose to your field staff.

In the example below, it shows how the work order automatically generated all the items, quantities, equipment and man-hours required to complete the job but by default the document is structured to leave out the pricing column. This can be much more useful than trying to blur or cross out pricing on a carbon copy that you hand over to the crew to complete the job.

With all the components listed above it is important to remember that your process and documentation need to be catered for your unique business. The purpose behind these descriptions is to show you the power that a proper all-in-one software system to hold for you. You have enough on your plate, help yourself and your team improve by removing the chance for error.

This post was written by green industry veteran and SingleOps account executive Sean Adams. It was published originally on his LinkedIn. To see how SingleOps can help your business, you can schedule a free online demo here.